Cities today – defined by their metro systems

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 24 June 2005 | Olof Persson, President, Mainline & Metros, Bombardier Transportation | No comments yet

Today, cities are growing and expanding, populations are increasing, and the need for improved, safer and modern mass transit is an absolute must. As populations extend to suburban areas to live and continue commuting to inner downtown areas to work, this need for efficient transportation has become the top priority for Government authorities. But just providing the vehicles to provide transportation is not enough.

As cities vie against one another (especially when competing for the chances to host events such as the Olympics, World Soccer matches and any other major events that attract foreign investments), mass transit suddenly becomes one of the distinguishing economic factors when decisions are being made.

Today, cities are growing and expanding, populations are increasing, and the need for improved, safer and modern mass transit is an absolute must. As populations extend to suburban areas to live and continue commuting to inner downtown areas to work, this need for efficient transportation has become the top priority for Government authorities. But just providing the vehicles to provide transportation is not enough. As cities vie against one another (especially when competing for the chances to host events such as the Olympics, World Soccer matches and any other major events that attract foreign investments), mass transit suddenly becomes one of the distinguishing economic factors when decisions are being made.

Today, cities are growing and expanding, populations are increasing, and the need for improved, safer and modern mass transit is an absolute must. As populations extend to suburban areas to live and continue commuting to inner downtown areas to work, this need for efficient transportation has become the top priority for Government authorities. But just providing the vehicles to provide transportation is not enough.

As cities vie against one another (especially when competing for the chances to host events such as the Olympics, World Soccer matches and any other major events that attract foreign investments), mass transit suddenly becomes one of the distinguishing economic factors when decisions are being made.

Cities today are in fact being defined not only by the historic and modern sites they provide their inhabitants and visitors, but also by the efficiency, safety, reliability and the aesthetic designs of their transportation.

Cities such as London, Berlin and Bucharest represent three different types of cities but each has many factors in common. Bombardier Transportation is proud to have been a major contributor to the modernisation of these cities by providing modern, reliable and aesthetic vehicles to these major European cities. Although many cities’ underground systems are old, some more than 100 years, the way the Government and other authorities have insisted on carrying on the tradition of efficient transportation methods while continuing to modernise and pave the way for the future of travel, these cities are prime examples of how history and tradition can merge with modernisation and visions for the future.

London Underground

The London Underground was the world’s first subterranean railway, opening in 1863. The first deep-dug lines for electric trains followed in 1890 and the system soon became known as the ‘Tube’.

The Tube is a system suffering from many years of under-investment. London’s population and employment have boomed in recent years putting enormous pressure on the operations and infrastructure of the network, which covers the majority of London and carries around three million passengers each day.

The London Underground PPP was finalised two years ago and is the biggest rail system upgrade project in the world at this time. Bombardier has a dual role in this showcase project as an equal shareholder in Metronet Rail, the project delivery company responsible for revitalising two-thirds of London’s underground rail system and as Metronet’s turnkey system supplier for new trains, signaling and future maintenance.

Whilst Metronet is responsible for regenerating the infrastructure, operating the system on a day-to-day basis remains in the hands of London Underground Limited. They retain responsibility for passenger service provision, including control and operation of trains and stations and responsibility for collecting and retaining all fares and other revenues. The statutory Safety Case is held by London Underground and meaning that overall safety responsibility remains in the public sector.

The Victoria line upgrade will be implemented first. Construction of the first of two pre-production trains is already underway in Derby, UK and will commence its testing program in 2006. The fleet of 47 eight-car trains will be phased into service from 2009.

For the Sub-Surface lines fleet, engineering work has already commenced and two pre-production trains will be constructed and supplied in 2008 with new trains being supplied to the Metropolitan line in 2009, Circle and Hammersmith & City lines in 2012-13 and the District line in 2013-15. All new trains will be of the same walk-through, fully air-conditioned design, with only the train length changing between the various lines.

Bombardier’s Movia metro train has been developed from Bombardier’s extensive experience of metro systems around the world and the new designs for the Victoria and Sub-Surface lines will meet all current London Underground standards. The flexible, modular system allows for a variety of train and door configurations, interior layouts and performances and so adapts to the small deep-tunnels of the Victoria line and to the extensive network of Sub-Surface lines.

The new trains will bring the following improvements:

- Significant reliability improvement over existing rolling stock, based on proven MOVIA technology

- Modular design for easier maintenance to ensure minimum downtime, lower maintenance costs and to facilitate future upgrades

- Excellent acceleration performance, leading to faster journey times

- Energy efficient, highly reliable solid-state Bombardier MITRAC propulsion systems

- Ergonomically designed and air-conditioned cabs for drivers

- Hard wearing, vandal-resistant materials and finishes to provide longer lasting and easier to clean exterior and interior environments

- More comfortable ride, lighting and heating/ventilation systems for passengers

- Bench style seating and tip-up seats to provide larger standing areas for peak time services

- Wide doors with stand-back areas and carefully designed interiors to improve boarding and alighting

- Facilities for disabled passengers to the latest standards including wheelchair spaces, improved signage and passenger information systems

- Closed circuit TV system to improve passenger security

Bombardier is responsible for the trains’ long-term maintenance, so we have every incentive to get the design right. With life-cycle costs and long-term maintenance in mind, the new trains for London Underground will be ‘designed for maintenance’. This in an innovative program that brings the designers of the new trains together with fleet maintenance staff who have years of experience of working on the London Underground network. Together, they share ideas that will ultimately make maintaining the new trains easier, as well as ensuring that they meet the various reliability targets throughout their operating life. The maintenance team also advises on the challenging operating conditions of the London Underground network.

Bombardier’s project delivery team’s ultimate goal is to meet the stringent performance targets determined by Metronet’s PPP Service Contract. The powerful combination of new trains and new signaling is designed to meet and wherever possible, exceed the set performance targets which include:

- Capability improvements – increased frequency of services and more passengers carried

- Availability improvements – increased overall reliability of trains and signal assets

- Ambience improvements – maintain high standards of cleanliness of trains through service and maintenance contracts

- Services points – benefits from faster rectification of minor faults to assets

Working closely with Metronet, partners, suppliers and subcontractors, Bombardier will ensure that the new trains and signaling systems are delivered to unsurpassed service availability levels, enabling Metronet to deliver their performance targets and London Underground to meet their operational requirements safely and reliably.

Though it is still in its early stages, the PPP is already beginning to deliver improvements. Good public transport is essential to support the development of London as a world city and as a further incentive, London will soon learn if it is to host the Olympic Games in 2012. Here, an effective public transport system is vital to the overall success of the event. The sustained level of investment secured by the PPP means that for next 30 years, money is already committed to transform the world’s first underground railway into a metro system expected of a capital city in the 21st Century.

Victoria line upgrade

- 47 new eight-car Bombardier Movia 248 trains

- A completely new signaling system and control centre

- Fleet maintenance from August 2007

Sub-Surface line upgrade

- 72 new eight-car Bombardier Movia 238 trains for Metropolitan line

- 40 new six-car Bombardier Movia 236 trains for Circle and Hammersmith & City lines

- 78 new seven-car Bombardier Movia 237 trains for District line

- Completely new signaling system and two control centres

- Fleet maintenance from December 2007

Berlin Metro

The history of the Berlin Metro dates back to 1902. In February of the same year, the Berlin Hochbahngesellschaft – a privately financed company – operated the first trains at an elevated track section. In its opening year, Hochbahngesellschaft transported no less than 20 million passengers.

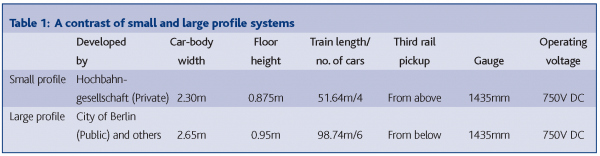

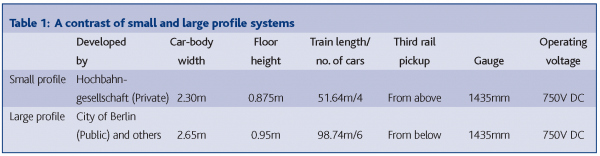

The end of the German Empire in 1918 saw the completion of Berlin Underground’s first extension phase. The result was basically the so-called small profile network Berlin currently has today, consisting of Lines U1 to U4. After World War I, the city of Berlin established a new underground operator with its own network and a new tunnel profile, the so-called Large Profile (now Line 5 to 9 in Berlin). This was the start up of later BVG, the present operator of buses, trams and metros in Berlin.

It should be noted that, except the very first Class A trains of Hochbahngesellschaft, all trains were delivered by or in cooperation with Bombardier or our predecessor companies. This cooperation results in a tremendous treasure of experience with the operational and technical requirement of the Berlin Metro system as our specialists and a long-term trustful cooperation creating a permanent win-win-situation between both partners.

A brief summary of the current situation:

- Employees: 3,100 (not including subsidiaries)

- Metro network: 144km in total, of which approximately 75% is underground, 25% at grade or elevated

- Number of lines: 9

- Number of stations: 170

- Kilometres travelled daily up to 400,000km and annually approximately 132 million km

- Ridership: 400 million passengers each year

This makes the Berlin Metro by far the largest single metro system in Germany. As a comfortable, environmentally friendly and state-of-the-art mass transit system for a bustling capital city, Berlin Metro has everything going for it in terms of inner-city transport. Instead of the usual stress on congested roads, it provides passengers with a fast and uncomplicated way of moving around the city, with trains arriving every few minutes. In addition, links to the city’s other mass transit systems – the bus, tram and S-Bahn services – are being constantly improved to provide connections that are straightforward and waste no time.

The vehicles deployed on the current metro fleet are relatively old. The modernisation program and a superb maintenance system provide a high level of reliability, even for ageing vehicles. The large profile fleet is now partly modernised after delivery of 46 Class H train-sets from Bombardier Transportation. For the small profile fleet, the replacement of older trains will be performed gradually with arrival of the new HK trains being under production at Bombardier’s site at Hennigsdorf near Berlin.

The new Class H and HK vehicles, currently the pride of the fleet, were intentionally developed in parallel and are distinctive both in terms of their similar appearance and a variety of other features they have in common.

Overview of some of the basic parameters:

- Open gangways permit unrestricted movement along the length of the units.

- All carbodies are of a welded construction consisting of extruded aluminum profile sections. The glass partitioned driving cabs at each end are of a GFR sandwich construction, with an emergency door integrated into the glass partition. All windows are bonded into the body shell. The passenger doors are sliding plug doors. The longitudinal seat is the traditional seating arrangement for Berlin Metro, which also permits greater passenger capacity.

- The bogies are almost identical, since they are designed for the same gauge.

- Braking in normal operating mode is by means of the electro-dynamic brake down to 15km/h, when the electro-pneumatic brake is applied. A specially designed brake controller ensures a smooth transition between braking systems, providing a high level of passenger comfort in all phases of the braking operation.

- The trains all receive their power from three-phase inverters.

- Passenger information is provided via an IBIS system, which controls both displays and digital PA announcements.

- The passenger saloons are provided with heating and ventilation systems. The Class HK driver’s cabs also have air conditioning.

- To safeguard our environment, care was taken even at the design stage to avoid the use of materials that, according to our current knowledge, could lead to problems during manufacture, disposal and recycling. We also regard the energy saving achieved by the use of lightweight construction techniques throughout and regenerative braking as an important contribution to reducing the impact on the environment.

According to what we have heard from BVG, the introduction of Class H (large profile) and HK (small profile) vehicles into regular passenger service has resulted in a new dimension of travel comfort. End-to-end access in the trains provide greater safety and even more utilisation of seats and standing space for passengers, due to the increased freedom of movement along the entire length of the train. Modern ventilation systems provide a pleasant interior climate throughout the train and bogies with air suspension significantly improve ride comfort.

Automation

The first automation projects at BVG were implemented back in the 1980s, when Lines U4 and U9 were equipped to allow the trains to be operated automatically. In such cases, the drivers remained in the driving cabs for safety and monitoring reasons.

When ordering the Class H trains, BVG, together with Bombardier Transportation, ensured that these trains were already equipped for conversion to automatically, driverless operated units.

This enabled BVG to pursue a project that is probably the most ambitious project ever undertaken by the Berlin Metro – known as STAR 2000 (STAR = ‘System Technology for Automatic Regular operation’). From November 1999 to April 2000, driverless operation trials were performed on a four-kilometre section of track between the Tierpark and Biesdorf South stations (A part of Line U5), including tests on how the system behaved in emergency situations. Trials were carried out with normal services running.

Besides BVG itself, Bombardier Transportation (at that time Adtranz) and Siemens were also involved in setting up this system. Financing for a major part of the system was provided by the German government using federal funds.

STAR 2000 is an experimental system. The feasibility of introducing AGT operation has now been demonstrated by this system forming an important step in the course of development of driverless systems in Europe. Other operators widely used the results of these trials.

BVG plans to use AGT on Line U5, providing the line extension will be completed.

New generation of metro trains for Bucharest

The Bucharest Metro Administration (currently called S.C. METROREX S.A.) was established in 1977. Two years later, the first metro line in Bucharest entered into operation with six stations equaling almost 9km in distance

Due to the rapid development of the city, the Bucharest metro network was gradually increased and today has four lines, 62km and 45 stations. In the near future the network will be extended by another 7.4km and six stations.

The current METROREX rolling stock fleet consists of 502 Romanian made metro cars and 108 Movia metro cars delivered by Bombardier Transportation between 2002 and 2004. Following a tender finalised in 2004 and as a confirmation of the high quality state-of-the-art MOVIA trains, Metrorex will acquire anther 120 new Movia metro cars from Bombardier Transportation.

The production of the bogies will take place at Bombardier’s Siegen plant in Germany and the flat pack carbodies will be produced in Bombardier’s Gorlitz plant in Germany. The IGBT propulsion will be manufactured in Bombardiers’ Vasteras plant in Sweden and the project management will be operated out of Sweden as well. Final assembly of the cars however will be completed in Craiova, Romania by our local partner Electroputere.

The Bucharest MOVIA metro trains have the following main characteristics:

- Length over couplers: 112.6m

- Six-car fixed configuration (four motor cars and two trailer cars)

- Stainless steel, bolted technology carbody

- Intermediate gangways

- Longitudinal seating arrangements

- Standing capacity: 984 passengers

- Seating capacity: 216 passengers

- IGBT converters

- Three-phase asynchronous motors

- 67% motored axles

- Self-steering wheel axles

- MITRAC control system

- Forced ventilation in passengers compartment

- HVAC in driver cabs

- ATP and ATO

Our MOVIA metro trains currently running in Bucharest have proven to our customer that the product is reliable and safe. Passengers also appreciate the comfort of these cars.

The MOVIA trains provide a modern feel to Bucharest, a capital city in continuous development, with a population of approximately two million inhabitants. The street traffic in Bucharest becomes more and more hectic and the importance of the underground transportation will increase significantly in the future. The introduction of the MOVIA trains will support the local authorities in their efforts to create a more fluent, safe and environmentally-friendly traffic in Bucharest.

The future Metrorex projects are especially related to the network line extensions like: Drumul Taberei-Eroilor (6.7km, ten stations), Eroilor Universitate (2.3km, three stations) and on a longer term the connection to the Bucharest International Airport (12.5km, nine stations).

Bombardier Transportation is also involved in the renewal of the existing signaling and CTC equipment from the Bucharest metro. The project for Line 2 will be finalised soon and the project for Lines 1 and 3 will be commissioned in 2007.

Issue

Issue 2 2005

Related modes

Metro

Related organisations

Bombardier Transportation

Related people

Olof Persson